Seawater filtration - the future in the fight against drinking water scarcity?

Seawater covers more than 70% of the Earth’s surface and represents more than 95% of the planet’s water supply. It is undrinkable, leaving almost 790 million people without access to clean drinking water. Scientists around the world are looking for an effective way to desalinate seawater quickly and cheaply. Nanofibre filters are a promising means.

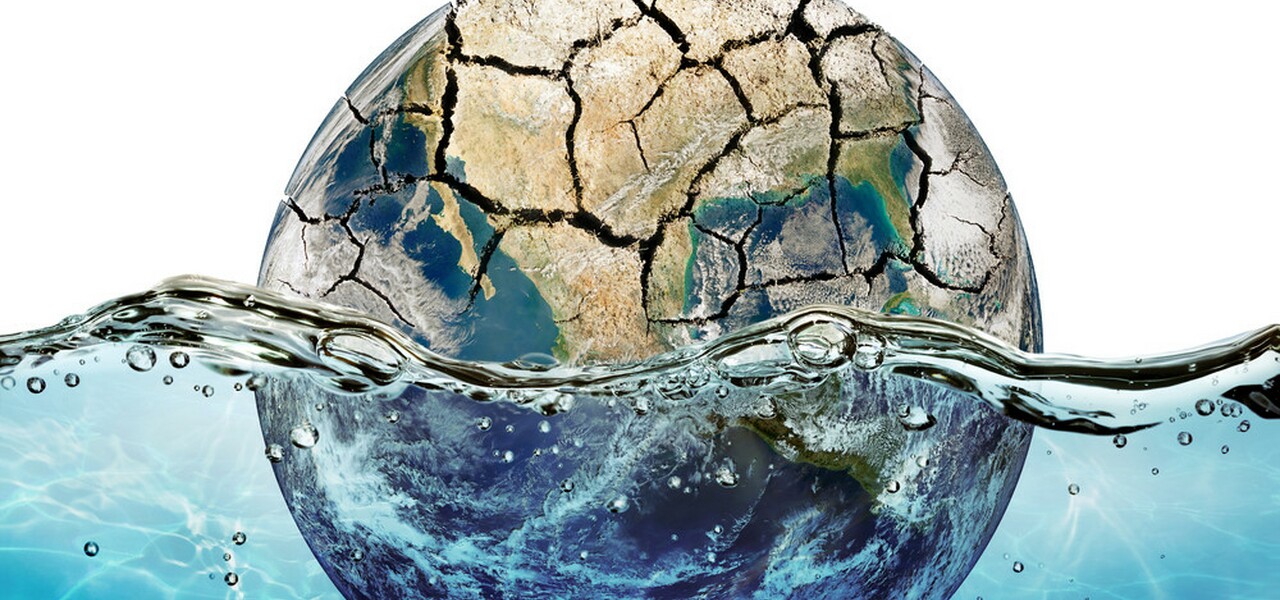

Water Scarcity Due to Climate Change

Fresh water, needed for most human activities, accounts for just 2.5% of the total amount of water on the planet. Changing climatic conditions mean less rainfall and drying rivers, forcing some countries to declare a water emergency for the first time in history.

Not surprisingly, desalination of seawater seems to be the easiest way to solve this problem. Unique nanofibre filters help, but even they have their own limitations. One of them is unwanted membrane wetting.

Unique Desalination Method Using a Filter with 99.99% Efficiency!

The process of distilling salt water with a nanofibre membrane was first introduced by a Korean research team. The new desalination technique is fast, and it takes only a few minutes to purify the water and make it drinkable. In addition, the filter offers an efficiency of an incredible 99.99%!

Engineers believe that commercialising such technology will help humanity cope with the lack of fresh drinking water in the future. One of the biggest problems faced by the nanofibre filter is membrane wetting. This causes fouling of the product and a reduction in membrane performance.

If the membrane becomes wet during distillation, it must be replaced immediately.

The 3D structure of the membrane and the evaporation process removes salt from the water!

The membrane of the filter has a 3D structure, which has been achieved by electrospinning. Using this technology, scientists are able to produce a hydrophobic, i.e. water‑repellent, membrane, a crucial step in seawater filtration.

The hydrophobic membrane is designed to prevent the passage of water molecules. Instead, a so‑called temperature difference is induced on both sides of the membrane, causing water on one side to evaporate. The membrane allows the water vapour to pass through, and it condenses on the cooler side. This is called membrane distillation. However, the salt particles are not converted to a gaseous state. They get trapped on the inlet side of the membrane and stay there. This results in pure, fresh, drinkable water.

The Korean scientists apply a silica aerogel to the nanofibre membrane. This improves the passage of water vapour, giving faster access to the desalinated water. The team tested their technology in continuous operation for 30 days and found that the membrane filtered out 99.99% of the salt without any wetting problems.

Advantage over Conventional Distillation Equipment!

A study on an improved filter capable of desalting seawater in continuous operation for a month appeared in the renowned Journal of Membrane Science. Dr. Yunchul Woo commented: “The nanofibre membrane has the potential to filter seawater without wetting. We are working to make it suitable for commercial use, especially in third world countries. It has proven itself in a pilot study, and the team of scientists is working tirelessly on the possibility of producing it on an industrial scale.”

Currently, reverse osmosis is the main method of seawater purification used in around 20,000 desalination plants around the world. However, these plants require huge amounts of electricity to operate. In addition, they produce "concentrated brine" as a waste product, which is usually dumped back into the sea.

What Does the Future Hold?

Scientific teams around the world are now trying to modify the composition of the nanofibre membrane so that it can operate continuously (and without risk) for more than a month.

The hydrophobic nature of the filter delays the risk of wetting, but it still exists. Development of a membrane that would resist unwanted wetting is now the number one priority.

Researchers have also recently introduced a new technology for producing water from air. Whether these new methods will take off remains to be seen.

Sources Used:

- https://newatlas.com/materials/desalination‑membrane-coaxial‑electrospinning-nanofibers/,

- https://interestingengineering.com/nanofiber‑membrane-filters‑999-of‑salt-from‑seawater-within‑minutes,

- https://www.inceptivemind.com/nanofiber‑membrane-makes‑seawater-drinkable‑minutes/19959/,

- https://www.engadget.com/nanofiber‑membrane-drinking‑water-150039679.html?guccounter=1&guce_referrer=aHR0cHM6Ly93d3cuZ29vZ2xlLmNvbS8&guce_referrer_sig=AQAAAJpGtmAkipgT02kfcQHcyTKZJXxy8AtGTWwNN8Tpa9sM9iN7hmdmjqifYL‑Y4M3HJ85P_NM5ux_-2g‑ErD3WYcDynbTxYZ-SgJ336EumKEBXExAOMWSpRfBMLZ8_Tf6kYoaOCi4M5N5dfp‑AjSGKwzs__JkP8qtdBuIitJe342WW.