Waterproof and breathable clothing

Nanofibers have the ability to create performance apparel with entirely new properties. Simultaneously breathable and protective. Composite material with nanofibers is the basis for any performance apparel.

A unique combination of great features

The performance of nanofiber‑enriched composite materials can be optimized through a unique combination of nanofiber layer properties:

high specific surface area

light-weight

very small fiber diameter

high water vapor permeability

chemical functionalization

high porosity (> 80%)

Nanotechnology significantly improves your existing products

LINEA line

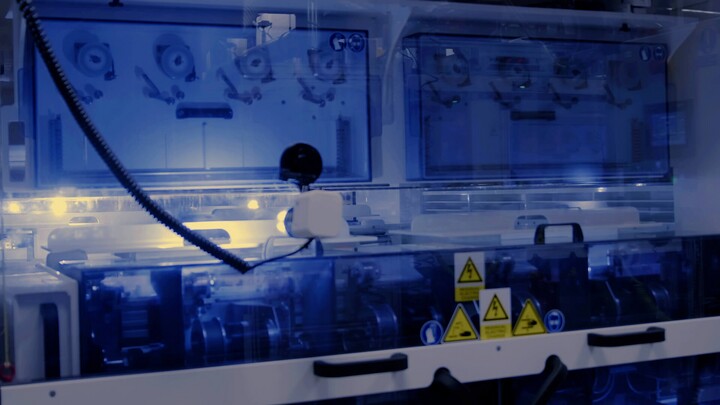

The LINEA line enables the production of nanofibers in large volumes.

It is designed for ease of use, scalability, modularity, and flexibility to produce the highest quality nanofibers for all types of performance apparel.

Contact us